Ion Vapor Deposition (IVD)

IVI has been designing and manufacturing Ion Vapor Deposition (IVD) systems for over 40 years.

IVI’s IVD Facilities have proprietary features that provide ultimate performance and productivity.

IVI’s IVD Facilities are utilized for primarily depositing aluminum. Ask about other deposition materials.

Parts to be processed may be steel, titanium, aluminum alloys and other metals – providing high performance corrosion protection and cosmetic appeal. Ask about other processed parts materials.

IVI’s IVD Facilities offer significant Advantages:

-

Cost effective, highly efficient operation when compared to competing processes

-

Provide a dense coating having excellent adhesion, thickness uniformity and temperature capability

-

Ion Vapor Deposited aluminum replaces cadmium plating and may be used at temperatures up to

925o F as opposed to cadmium plating which has a limitation of 450o F -

IVD, in addition, is a green process in regards to the environment.

-

Corrosion protection for fasteners, hardware and high stressed parts

-

Satisfy MIL Specifications

Fields of Application include:

-

Aerospace

-

Automotive

-

Metal Manufacturers

-

Private Aircraft

-

Appliances

-

Commercial Coating

Fasteners

Petroleum

Cooking Utensils

Electronics

Sporting Goods

Fasteners

Petroleum

Cooking Utensils

Electronics

Sporting Goods

Features of IVI’s IVD Facilities:

-

Outstanding Productivity

-

IVI’s Specially Designed “Quadri-Phase”TM Vacuum Pumping System provides phenomenal gas handling performance on all IVD Systems – an extremely important feature for the IVD process.

-

Totally Integrated for Ease of Installation/Access

-

Fully Functional Computer Control

-

Excellent Operator Access

-

Fully Automated Source Control

IVI’s IVD Twin Barrel Facility

IVI’s IVD Twin Barrel Facility

-

Handles large quantities of fastener and hardware parts

-

Conveniently designed for loading and unloading parts

-

Ask about the many features of IVI’s Twin Barrel Facility that simplify your productive capacity.

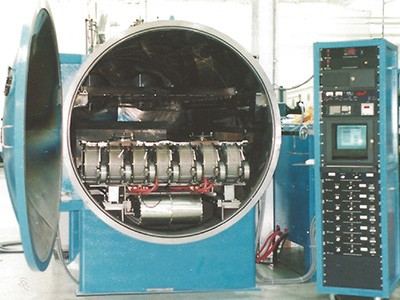

IVI’s Series 4200 Model 72144 Rack Mounting IVD Facility

IVI’s Series 4200 Model 72144 Rack Mounting IVD Facility

-

Has the capacity to coat large parts and multitudes of smaller, irregular shaped parts

-

Optionally available with twin barrel coating capability for high productivity of small parts and fasteners

IVI’s Series 4200 Model 84120 Oversized Rack Mounting IVD Facility

-

Has the capacity to coat larger parts than the Model 72144 and also multitudes of smaller, irregular shaped parts

-

Optionally available with twin barrel coating capability for high productivity of small parts and fasteners